Poranit-ES (P-ES)

Porous chrome steel for venting injection molds

P-ES45 in action (German)

P-ES45 in action (English)

P-ES45

Serviceliste

-

DensityListenelement 13,80 g/cm³

-

Shore D hardness / hardness // BrinellListenelement 296 / 32 HBW (5/125/10)

-

Pore size / pore quantity // pore size / pore quantityListenelement 39 µm / 18 %

-

E-Module (DIN EN ISO 178)Listenelement 447,9 MPa

-

Long-term heat resistance250 °C

-

Verglaungstemperatur / Glass transition temperature287,5 °C

-

thermal expansion coefficient17.851 (x 10-6K-1)

P-ES100

Serviceliste

-

DensityListenelement 13,80 g/cm³

-

Shore D hardness / hardness // BrinellListenelement 296,5 / 31 HBW (5/125/10)

-

Pore size / pore quantity // pore size / pore quantityListenelement 326 µm / 25 %

-

E-Module (DIN EN ISO 178)Listenelement 447,9 MPa

-

Long-term heat resistance250 °C

-

Verglaungstemperatur / Glass transition temperature287,5 °C

-

thermal expansion coefficient18.231 (x 10-6K-1)

subtitle

Poranit ES-45 is a high-strength, porous material made of chrome steel and is primarily used for venting injection molding tools. The surface can be sanded and polished.

Poranit ES-100 is a high-strength, porous material made of chrome steel and is mainly used as ventilation steel in blow extrusion tools.

P-ES-45 P-ES-100 represent a cost-effective alternative to sintered ventilation steels.

P-ES prevents gas fires and thus soot on the plastic part. Damage to the tool through deposits and corrosive oils due to thermal decomposition can be avoided through an intelligent arrangement of P-ES. Problems caused by compression resistance and the resulting shrinkage in the injection process are eliminated by using P-ES.

This reduces the molding pressure, accelerates cooling and even thin-walled parts can be produced with high cycle rates.

P-ES is cleaned by surface treatment with MEK (methyl ethyl ketone) or by burning it out at approx. 180 ° C. Diffuse capillarization means that there are few mechanical claws on the surface of PES due to K residues.

P-ES is suitable for all thermoplastics.

P-ES is conditionally suitable for:

- PVC-HPUGummi

By reversing the air after each shot, it may also be possible to use P-ES with plastics that are suitable to a limited extent.

P-ES is made from chrome steel granulate and is therefore STAINLESS!

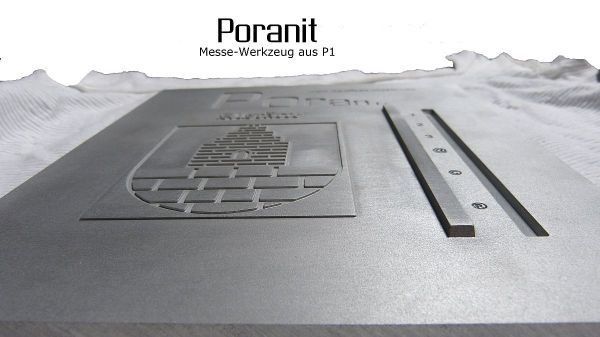

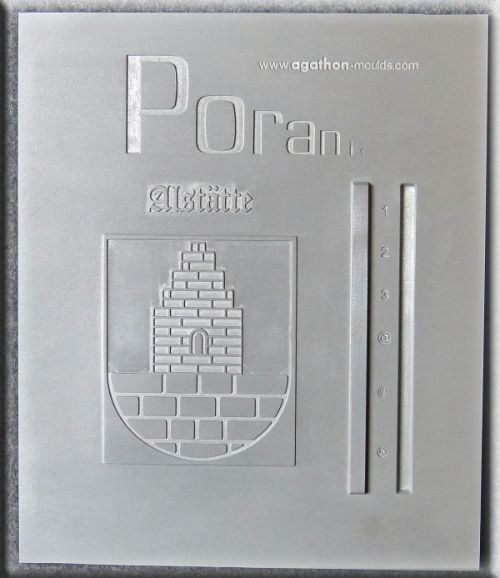

P-ES semi-finished products are now also used in many other areas. The proven enormous surface hardness combined with homogeneous air permeability is the result of goal-oriented research and development. The intensive cooperation with our customers has already led to optimized production processes and end products that were previously not feasible without Poranit.

Poranit ES is a product from Bioenergie Rhein-Ruhr GmbH